Crowdsourced 3D printers: Photos of Kickstarter’s 10 most successful projects

Image 1 of 10

Micro 3D Printer

We wrote about this one after Maryland-based M3D raised more than $2 million in the first two days of its campaign on Kickstarter for the seven-square inch Micro desktop 3D printer. It has now raised over $3 million in funding. The printer was so popular because of its tiny size, ability to easily print small items, and its simple user interface. Right on the screen, people can choose from objects to print or download directly from open source websites that have designs.

Formlabs Form 1

Formlabs Form 1

Formlabs, a MIT Media spin-off, created the Form 1 3D printer, which raised $3 million on Kickstarter and then $19 million in Series A funding. The printer comes with software and a post-processing kit with tools to clean the workspace and organize for the next time you use the machine. It was one of the first low-cost desktop 3D printers when the campaign closed in October 2012. The Form 1 is a stereolithography printer, which uses higher resolution and thicker structures than fused deposition modeling.

Buccaneer

Buccaneer

In the summer of 2013, Pirate 3D built a home 3D printer for consumers called the Buccaneer. The printer pulls designs directly from the company’s store, Treasure Island, and connects with a PC or mobile device to print from anywhere using wireless internet. The Buccaneer is about $400. Pirate raised more than $1 million on Kickstarter, though their original goal was only $100,000.

Rigidbot

Rigidbot

Around the same time as the Buccaneer came the Rigidbot, which debuted on Kickstarter as well. It also raised over a million dollars. The printer comes assembled or as a kit, and is expandable to several different sizes. The first order has already sold out and the next round ships in July.

LIX 3D printing pen

LIX 3D printing pen

The LIX works like a 3D printer. There is no ink; instead, it uses plastic filament that melts to create structures of any size and shape. The pen is powered by a USB 3.0 port, and the filament is fed through the top of the pen and it takes 60 seconds to heat up. The Kickstarter campaign has raised almost a million dollars and still has three weeks to go, at the time we’re writing this. The LIX is marketed as the smallest 3D printing pen in the world that can create rigid, freestanding structures, and the company plans to start shipping in the fall.

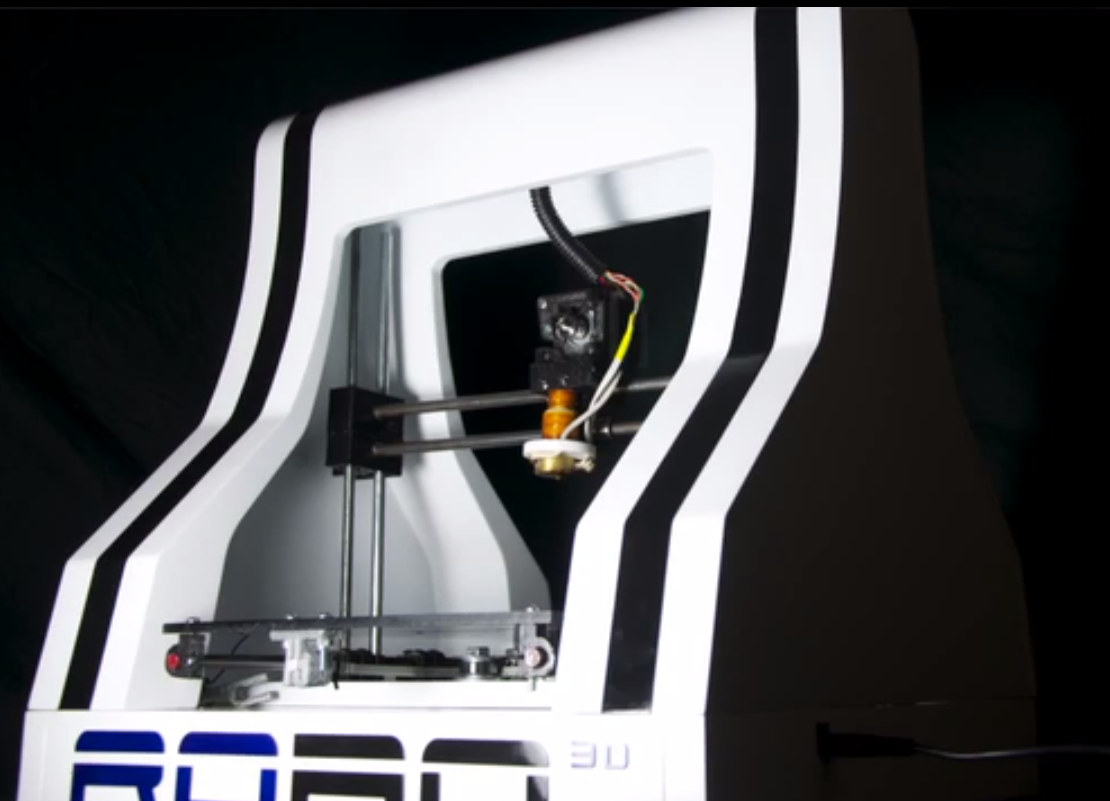

RoBo 3D

The RoBo 3D printer is low-cost, open source 3D printer that originally sold for about $500 on Kickstarter at the end of 2013. It came either assembled or as a kit, and is now avaialble on the company’s website for $799. The RoBo team marketed it as a competitor to the MakerBot Replicator 2, which seemed to bode well because they raised $650,000, which was well over their goal of $49,000.

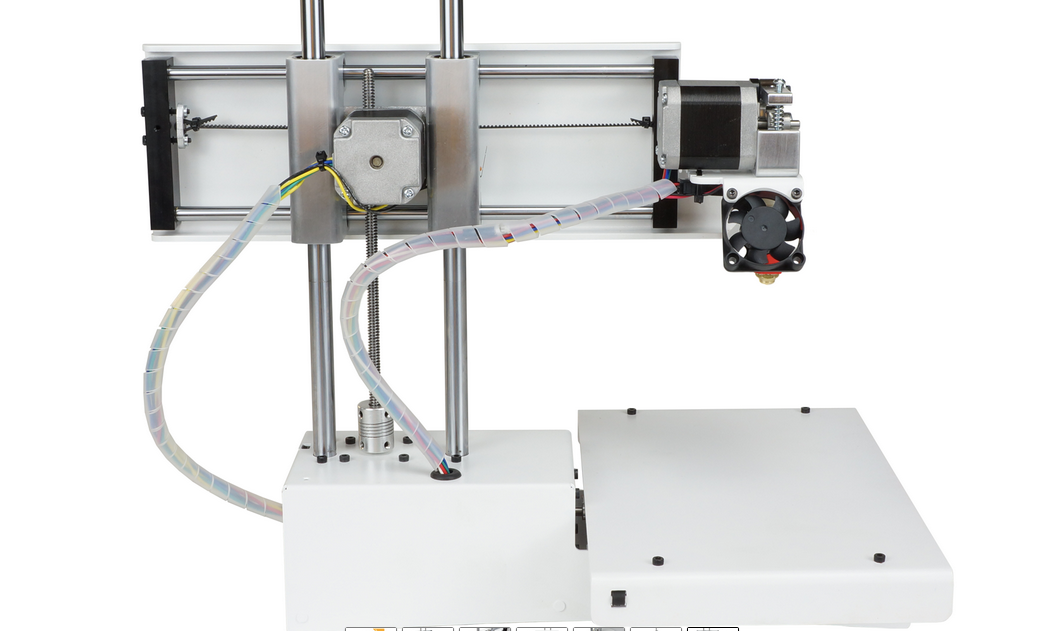

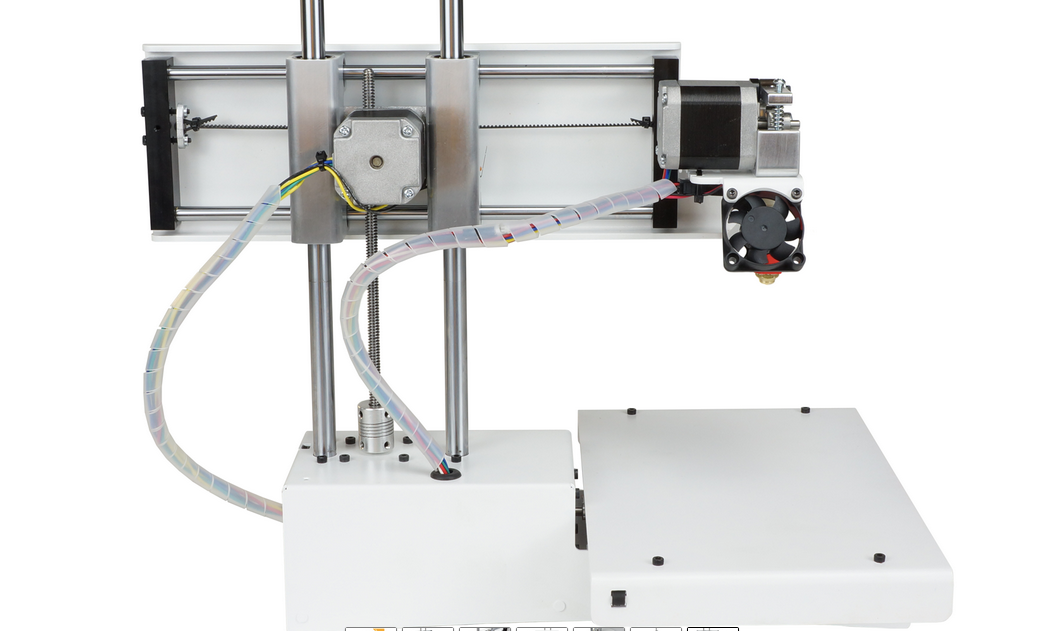

Printrbot

Printrbot

The Printrbot was one of the first 3D printer kits that users could build at home, launched back in 2011. The creators were inspired by the RepRap design — building a self-replicating machine. The kits run at about $600 assembled, and there are several generations on the site.

Pegasus Touch

Pegasus Touch

The Pegasus Touch 3D printer raised more than $700,000 over its initial goal in February of 2014. The first machines are already shipping to the first backers. The printer was manufactured by FSL3D, a leg of Las Vegas company Full Spectrum Laser that is trying to rival MakerBot’s models with this new printer. The Pegasus Touch runs at about $2700, so it isn’t exactly comparable to any of the other printers on this list, but it did very well on Kickstarter for being so expensive.

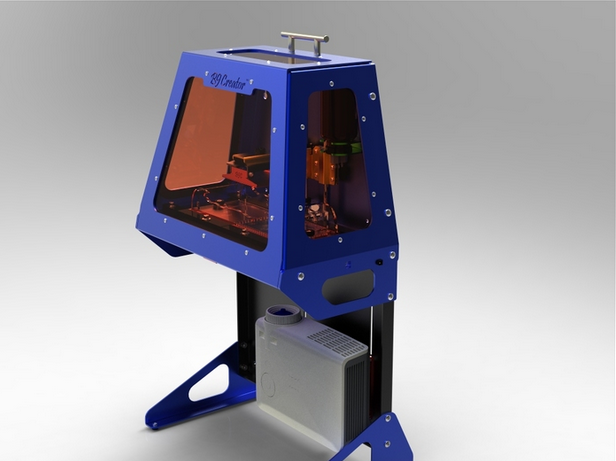

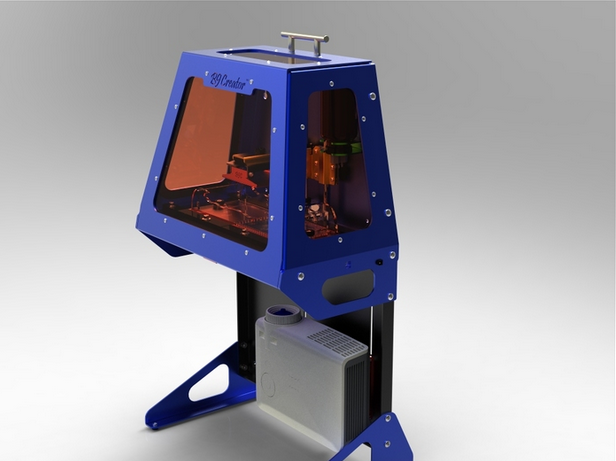

B9 Creator

B9 Creator

The B9 Creator had less than 400 backers and raised more than $500,000. It was marketed as a DIY 3D printer that uses open source software and a photo-initiated polymer resin basin. It comes as a kit that can be assembled with basic tools. The website says the printer moves faster than a fused deposition modeling printer, and the product has been shipped.

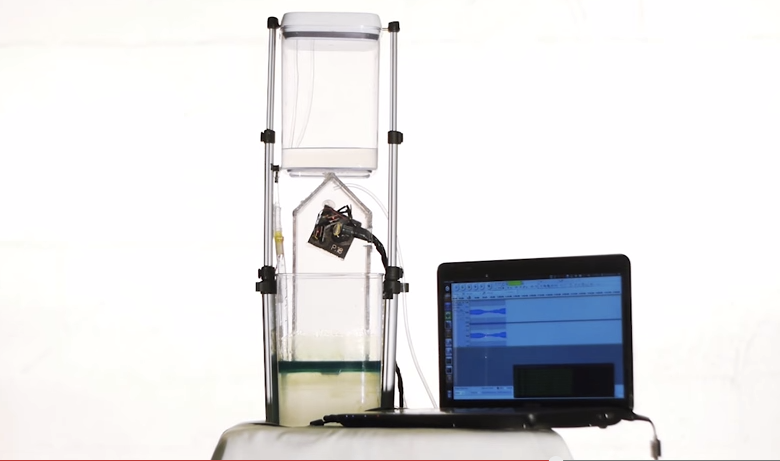

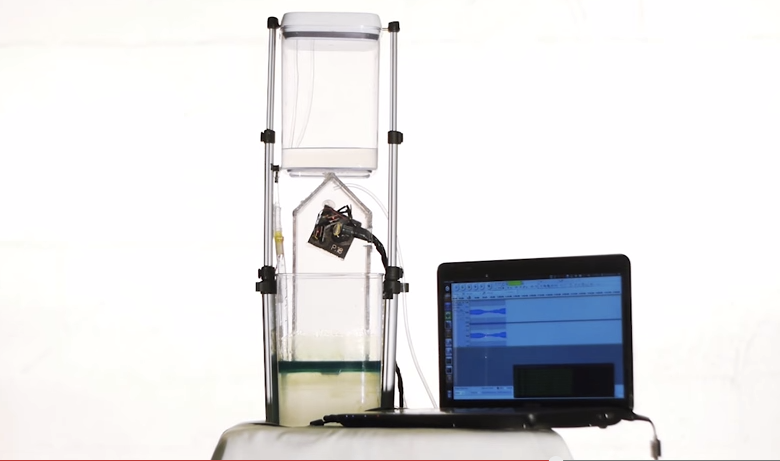

Peachy Printer

Peachy Printer

The Peachy Printer is a photolithographic printer. It uses a controlled beam of light to cure light sensitive resin into hard objects. A laser beam moves along the X and Y axes to create the shape of the object, and the Z axis uses a drip system with an electrical connection and salt water, which determines the height of the object. The printer connects with the company’s software called Blender, which uses an audio wave file to direct electromagnetic mirrors. It’s a strange way to 3D print, and we’ve never seen anything of the like, but this project was fully funded after 30 days. It raised more than $650,000, well over its $50,000 goal. Watch this video to understand more about how it works.

-

Account Information

Contact Lyndsey Gilpin

- |

- See all of Lyndsey's content