Photos: The 3D printed moon base of the future

Image 1 of 11

A 3D printed moon base

The European Space Agency has been talking about 3D printing a moon base since last year. It’s always been a distant thought. But recently, in partnership with Foster+Partners architectural firm, the ESA released a video showing how they could conceptualize the lunar base.

Lunar lander

In a video (which describes the hypothetical trip to build a lunar base), this unmanned lunar lander detaches from a rocket launch and is on a course to the Shackleton Crater, which is at the South Pole of the Moon. The crater is an ideal location for the base because the area gets plenty of sunlight.

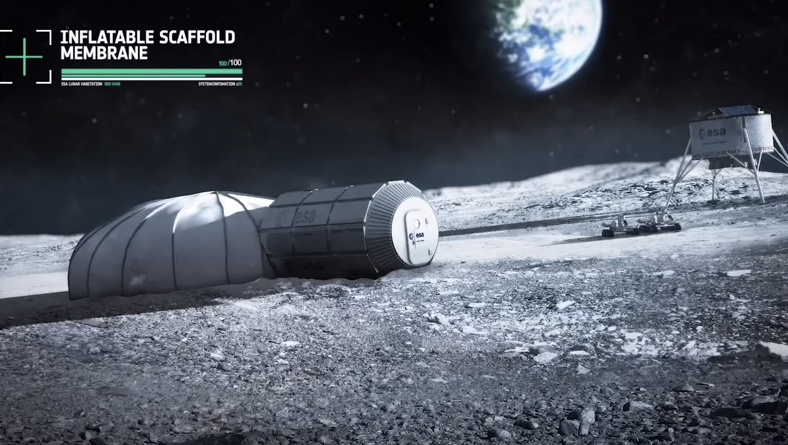

The dome

After the lunar lander, which contains an inflatable dome and two robot 3D printers, lands on the moon and the cylinder is unloaded, a dome is inflated. It provides the support structure for construction.

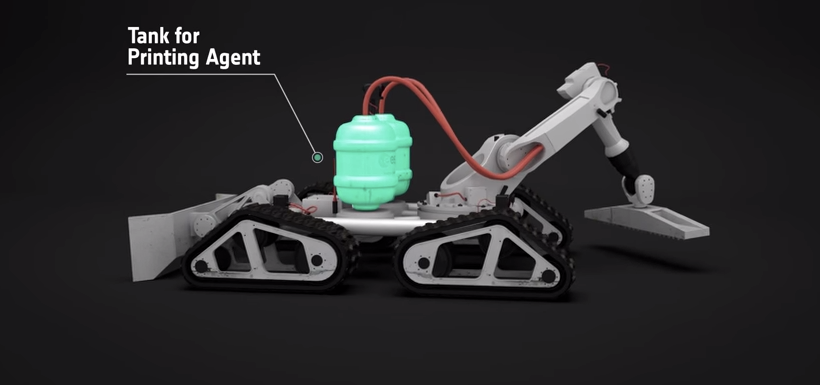

The robot

The habitation would be built by the robot 3D printers. On one end there is a scoop that collects regolith — or moon dust. In the middle are tanks with the printing materials. There is also a six-axis robot arm and a printing head.

Moon materials

The robot collects regolith from the moon’s surface and takes three months to layer it over the dome as a protective shell. It is light, yet strong. This layer would protect people from temperature fluctuations, radiation, and meteoroids.

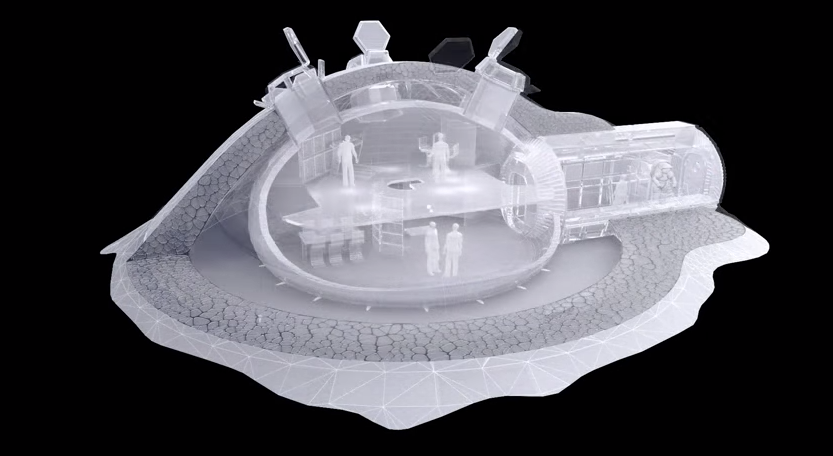

The lunar base

When it’s complete, the lunar base will be able to house four people comfortably. The skylights draw daylight, but the workspaces and living spaces are sheltered from the pressurized atmosphere.

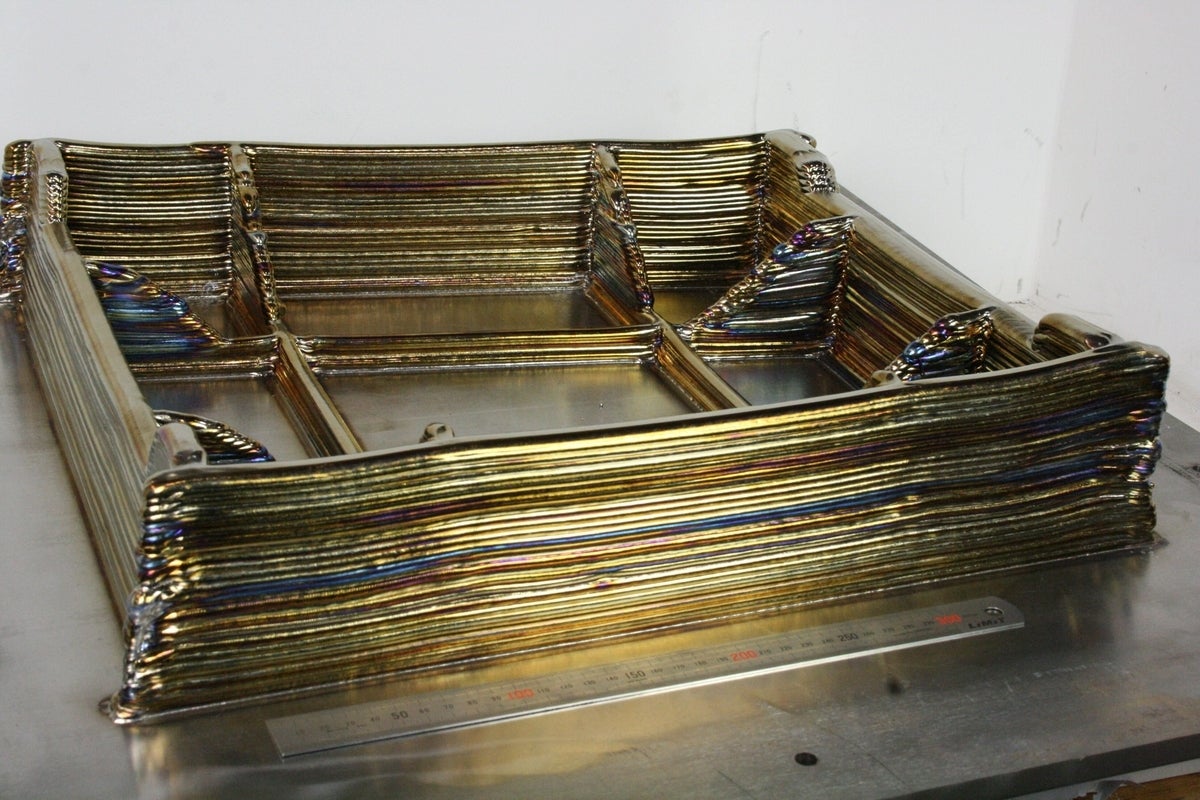

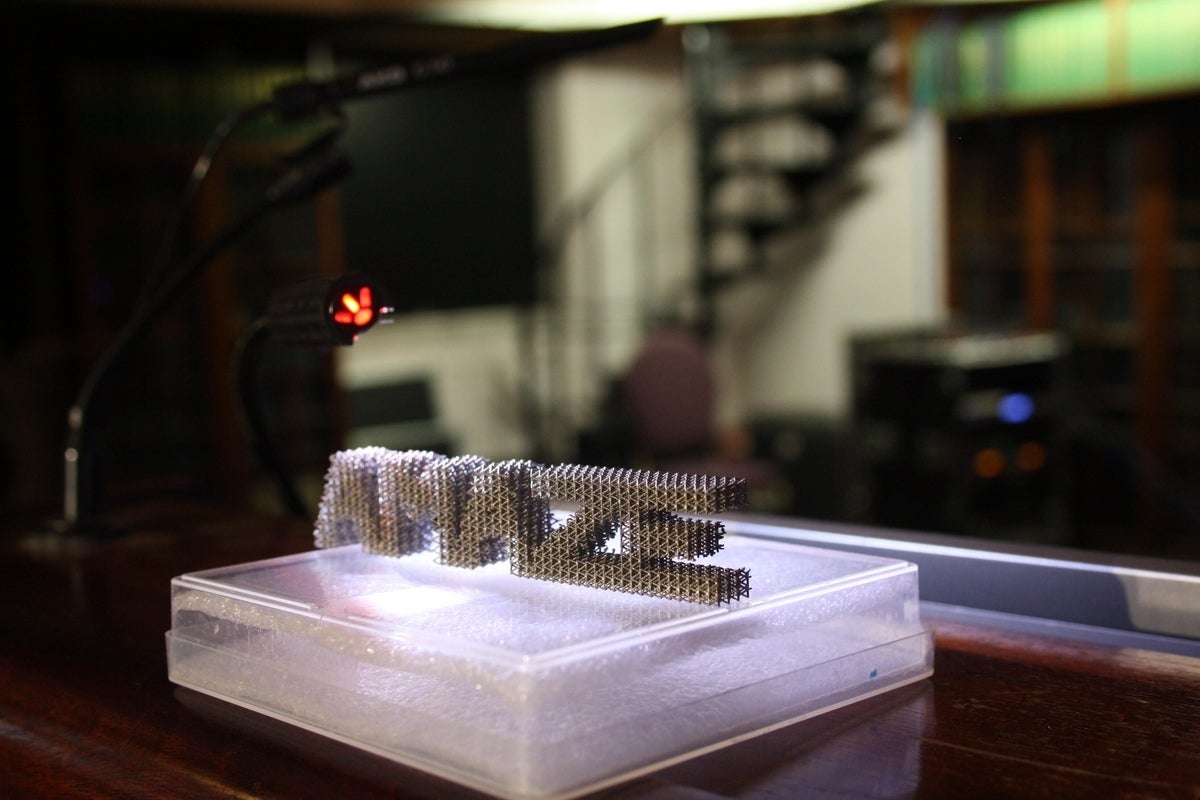

Aeronautics demonstrator

The ESA is experimenting with many types of 3D printing materials. This aeronautics demonstrator is made of titanium and was made with a 3D printer.

AMAZE

AMAZE — Additive Manufacturing Aiming Towards Zero Waste & Efficient Production of High-Tech Metal Products — is a project that involves 28 industrial partners in Europe. The teams are working with materials that can withstand temperatures up to 3500u00b0C — many of them could possibly be used in space. The titanium they are printing is the most flexible titanium ever 3D printed.

Lunar 3D printing

For the ESA’s lunar base study, Monolite supplied a 3D printer to experiment with. They simulated lunar material with magnesium oxide to print with, then used salt to bind it and convert the material into a solid.

Lunar soil

This 1.5 ton block was 3D printed using lunar soil. It serves as an example for the ESA of what they could do with a moon base.

The future

Using local materials such as moon dust and lunar soil could make 3D printing on the moon much easier, according to the ESA. Here is a rendering of what they hope a lunar base could look like in the future.

-

Account Information

Contact Lyndsey Gilpin

- |

- See all of Lyndsey's content