3D printing is a critical advancement in the way products are designed and manufactured. For decades, 3D printing has been used for industrial purposes, to quickly produce parts for rapid prototyping before employing traditional manufacturing techniques. Now, with the increased precision of 3D printers, the sharp reduction in printer and material costs, and a substantive increase in the lifetime durability of 3D printed parts, many industries are adopting 3D printing as a form of just-in-time manufacturing to reduce design complexity, warehousing costs, and simplify supply chains.

For hobbyists, 3D printing allows for the custom creation of parts to meet the needs of their projects, such as a plastic housing for a circuit board. Websites like Thingiverse feature crowdsourced designs for replacement car parts to 3D printed art.

This cheat sheet about 3D printing is both an easily digestible introduction to a new paradigm, as well as a “living” guide that will be updated periodically to keep IT leaders in the loop on new 3D printing technologies and ways in which they can be leveraged.

SEE: Research: 3D printing 2017: Benefits, trends, enterprise applications (Tech Pro Research)

Executive summary

- What is 3D printing? 3D printing, also known as additive manufacturing, is a catchall term for a variety of technologies that allow for the creation of individual three-dimensional objects.

- Why does 3D printing matter? 3D printing allows for rapid prototyping of industrial parts without the costs of one-off prototype manufacturing. 3D printing can also be leveraged to create production-quality parts on demand, reducing the need for warehouses.

- Who does 3D printing affect? While additive manufacturing has been in use in industrial settings for decades, the rapidly decreasing cost of printers and various types of materials that can be used make 3D printers an economical solution for hobbyists.

- When is 3D printing happening? 3D printers have seen increasing popularity since 2010, as prices for printer hardware have fallen.

- How do I get a 3D printer? 3D printers are now ubiquitous enough that users can purchase one in big box electronic or hardware stores, and can be used with computers running Windows 10, OS X, or any modern Linux distribution.

- Free ebook: Executive’s guide to the business possibilities of 3D printing (TechRepublic)

- 3D Printing: Building the Future (ZDNet/TechRepublic special feature)

- Photos: 26 weird and useful things to 3D print for your desk (TechRepublic)

What is 3D printing?

3D printing is a catchall term that refers to a variety of additive manufacturing technologies first introduced in Japan in 1981. Different 3D printing technologies are used depending on the type of printer in use, and the type of material being printed.

Extrusion printing such as fused deposition modeling (FDM) or fused filament fabrication (FFF) is the most common type of printer, due in large part to the low cost of printing hardware and thermoplastic materials.

Photopolymer printers, which use a liquid resin cured by ultraviolet light, are increasingly affordable for small projects and hobbyists. Printers such as LittleRP and mUVe are attractive options, and they can use resin from third-party vendors such as MakerJuice at a reduced price. B9Creations is a high-precision photopolymer printer that is accurate to 30 micrometers, though the increased precision comes with a higher price tag.

SEE: All of TechRepublic’s cheat sheets and smart person’s guides

Powder bed printing allows for the printing of metal alloys, polymers, and other materials such as plaster and calcium carbonate. Various types of powder bed printers exist, including powder bed/inkjet head (3DP), electron-beam melting (EBM), selective laser melting (SLM), and direct metal laser sintering (DMLS).

For thermoplastics, selective heat sintering (SHS) and selective laser sintering (SLS) printers are available. These types of printers are generally rarer and reserved for industrial applications, with printer prices starting at $50,000 and exceeding $1 million depending on the type of printing, material used, and maximum printable area. Due to the cost of printers that work directly with metals, you may choose to use 3D printers to create a plastic mold for the traditional fabrication of metal parts.

Additional resources:

- Infographic: 3D printing is slow to catch on in the enterprise (TechRepublic)

- 3D printer sound test: Which machine is quiet enough for the office? (ZDNet)

- 3D printing hands on: Understanding the difference between Delta and Cartesian printers (ZDNet)

- Photos: Welcome to the next level of 3D printing (CNET)

- Download: 50 things you should know about 3D printing (Tech Pro Research)

Why does 3D printing matter?

Various industries can benefit from the increased speed and reduced costs of 3D printing compared to traditional methods of rapid prototyping. For engineering firms, having the ability to create an object using an on-site 3D printer (rather than sending the design to a manufacturing facility, perhaps on a different continent) can speed up a given workflow by weeks and save substantial amounts in courier fees alone. With in-house prototype manufacturing, worries of IP theft by a third-party facility are nonexistent. For finalized designs, 3D printing in manufacturing can reduce warehousing costs by moving to a just-in-time production model. This is particularly helpful for niche products with low install bases.

SEE: DIY-IT Project: 3D printing discovery series (ZDNet)

Volkswagen Autoeuropa estimates that the organization saved $160,000 in parts in 2016, while reducing project lead time from 40% to 90% by using Ultimaker 3D printers rather than external vendors for tools, jigs, and fixtures used for assembling automobiles.

Likewise, the ability to produce parts on-demand, as a form of just-in-time manufacturing reduces business overhead for warehousing and manufacturing. It also reduces losses on unsold inventory left to languish, which is subsequently sold at or below cost, if not simply discarded outright.

For creative works such as custom jewelry, 3D printed samples for design and fit are quick and cost-efficient demonstrations.

Additional resources:

- HP’s Metal Jet 3D printer may build your next car’s innards (CNET)

- Stratasys announces new scalable, automated, cloud-controlled 3D demonstrator (TechRepublic)

- Ford tests Stratasys 3D printer for large, personalized car parts (TechRepublic)

- Video: Celebrity Cruises designs ship for the first time using all 3D (TechRepublic)

- GE makes $1.4B bet on 3D printing, acquires two firms to boost additive manufacturing (TechRepublic)

- 3D printed parts give Honda’s McLaren race cars an advantage at Grand Prix (TechRepublic)

- Robot restaurants and sci-fi kitchens: How tech is changing the way we eat (TechRepublic)

- 3D bioprinter to reproduce human organs, change the face of healthcare: The inside story (TechRepublic)

Who does 3D printing affect?

In addition to the aforementioned industrial uses, 3D printing allows hobbyists to create unique items in their homes or local makerspaces and share those designs as parts in larger projects. Designers can share their designs on websites such as Thingiverse. This is particularly helpful for hardware projects, like a blade server-esque rack for Raspberry Pi units.

For car enthusiasts, 3D printing is an increasingly popular solution for replacement car parts, as stocks of original parts may be depleted or significantly marked up. The global nature of design sharing, combined with the relative speed with which 3D printers can produce items, is a significant advantage over waiting weeks for parts ordered from overseas to clear customs. Seemingly, no car or part is too obscure–users on Thingiverse have shared designs for things as small as replacement keyfob buttons for a 2003 Citroën Xsara Picasso, and a steering column bearing sleeve for the original Volkswagen Scirocco.

As 3D printing allows for the rapid, low-cost creation of single-use objects, it has been used to great success in biotech. Doctors have used 3D printers to treat children with tracheobronchomalacia, a medical condition which causes the windpipe to occasionally collapse, preventing normal breathing. With a customized splint designed to change shape and be absorbed into the body, patients diagnosed with this terminal disease have been cured. 3D printing has been used in veterinary biotech to create orthopedic knee implants, which fix common injuries in dogs’ hind leg ligaments. Kiosks which produce custom 3D printed foot orthotics have been developed in a collaboration between Go 4-D and HP.

Additional resources:

- Scientists hit milestone in 3D printing of cartilage (CBS News)

- 3D-printed bones? New ‘hyperelastic’ material could let doctors print implants on demand (ZDNet)

- 3D printing hands on: Lessons learned from my first big project (ZDNet)

- 3D printing hands on: How to easily customize objects to the exact size you need (ZDNet)

- How do you build on Mars? 3D printing from dust! (CNET)

- How 4 universities are using 3D printing to create ears, cartilage and blood cells (TechRepublic)

- How 3D printing could make robotic hands more affordable (TechRepublic)

- The startup that’s doing the impossible (TechRepublic)

- Photos: 10 incredible prosthetics made with 3D printers (TechRepublic)

Why is 3D printing controversial?

3D printing is rapidly reaching the level of becoming a social phenomenon, in much the same way that previous advances in technology (such as smartphones) were. The first Jolla Phone had official resources for users to print their own phone covers. Various other strange uses for 3D printing have been devised. 3D printing has made headway into the art world, with a 3D printed version of the Mona Lisa produced as part of a project for blind people to appreciate famous paintings.

The accuracy of 3D printers has led to groups attempting to produce 3D printed guns. The first of these, the “Lulz Liberator,” was released by Defense Distributed in May 2013, leading to an almost immediate legal action against the group by the US State Department, claiming distribution of the files needed to produce the guns are in violation of the International Traffic in Arms Regulations (ITAR). As a result, the files were pulled from Defense Distributed’s website. The group reached a settlement in July 2018, theoretically allowing the group to resume distributing the contested files, though a consortium of states have filed for a restraining order to prevent this. Defense Distributed was distributing the files in violation of the restraining order the following month. The future of Defense Distributed is in doubt following the resignation of founder Cody Wilson in September 2018, as Wilson was arrested the same month on charges of sexual assault.

In theory, one of the primary objections to 3D printed guns is the difficulty of tracing the origin of production, though a group of researchers at the University of Buffalo have devised a way to match patterns etched onto the surface of a 3D printed object to the printer which produced it, much in the same way manufacturing variations in paper and traditional printers make it possible to “fingerprint” forged documents.

As internet-connected printers become more ubiquitous, the security practices of 3D printer designs, among other Internet of Things (IoT) systems are coming under increased scrutiny.

Additional resources:

- 3D-printed gun controversy: Everything you need to know (CNET)

- MIT built a robot that can 3D print a building (CNET)

- Dubai unveils world’s first 3D-printed office building (CNET)

- Photos: 10 glimpses into the future of 3D printing (TechRepublic)

- 10 photos of 3D printed bridges, buildings and other supersized structures (TechRepublic)

- Photos: How NASA astronauts are 3D printing in space (TechRepublic)

- Intro to Unity 3D Game Development Bundle (TechRepublic Academy)

- 3D Programming with WebGL & Babylon.js for Beginners (TechRepublic Academy)

How do I get a 3D printer?

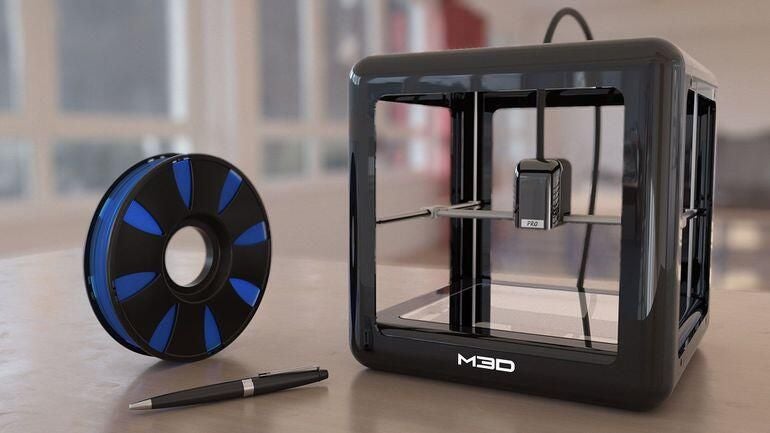

3D printers are increasingly ubiquitous. In the US, standard FDM printers can be purchased in various big box electronics and hardware stores for under $1,000. For the DIY crowd, you can build a 3D printer yourself with instructions from RepRap. For industrial uses, HP’s new Metal Jet 3D printing system is expected to ship in 2020, with pre-orders open now, though pricing per printer is “less than $399,000,” according to the company.

Before you decide which 3D printer to purchase, look to our sister site CNET for reviews of popular 3D printers to decide which one is right for you.

Additional resources:

- 3D printing in brief and a few printers for your consideration (CNET)

- M3D Micro 3D Printer review: A cheap (ish) 3D printer with cheap 3D prints (CNET)

- 3D Systems Cube 3 review: An excellent compact printer for making small 3D objects (CNET)

- XYZprinting Nobel 1.0 3D Printer review: Highly detailed prints at a high cost (CNET)

- Learn 3D Modelling and Texturing from Scratch with Blender (TechRepublic Academy)

- Hardware purchasing task list (Tech Pro Research)