Photos: 3D printed dentures, bike, surgical tools, and more

Image 1 of 9

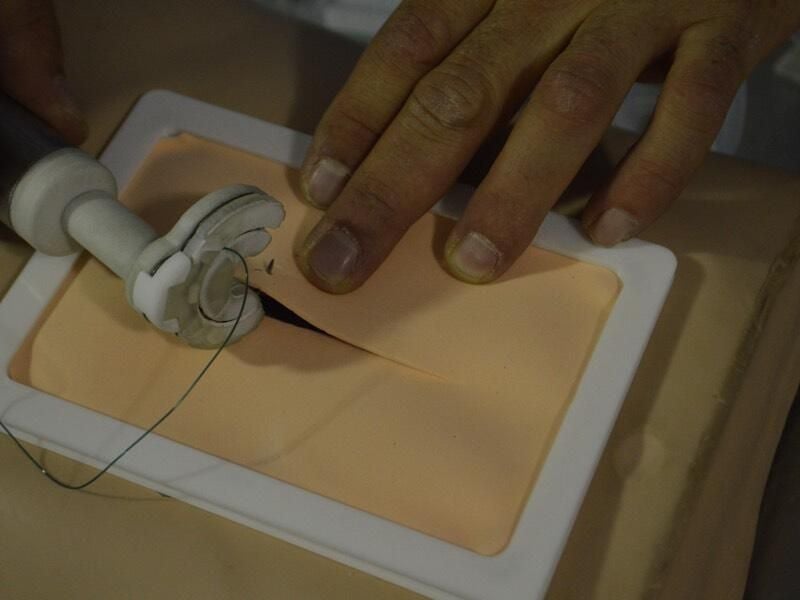

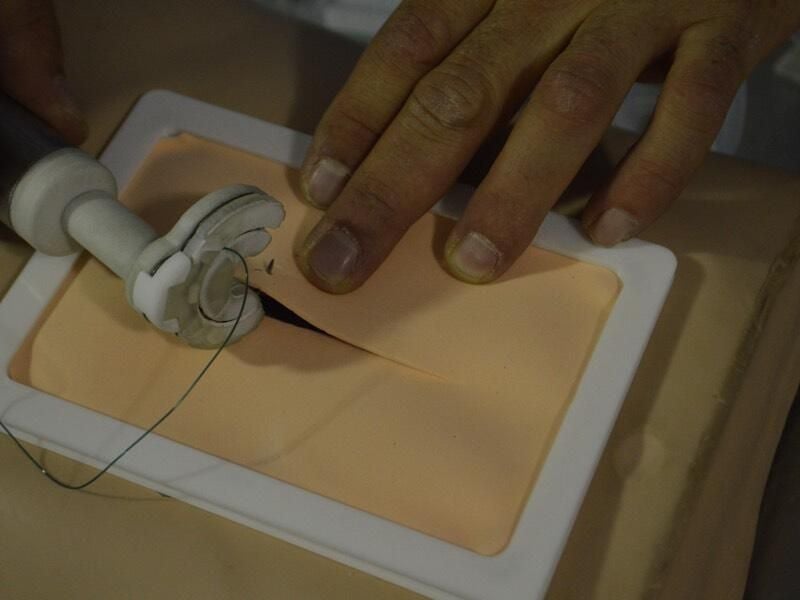

3D printed suturing tool

3D printed suturing tool

At GE’s Industry in 3D event, companies displayed their 3D printed wares and explained how each had been created using the technology.

A specialized, 3D printed suturing tool that doctors use for quicker stitches.

SEE: These 3 industries are kickstarting the 3D printing revolution

3D printed dentures

3D printed dentures

These dentures are one of many printed using additive manufacturing. Dentists can now create dentures like these faster than ever.

SEE: These 3 industries are kickstarting the 3D printing revolution

3D printed Bike

3D printed Bike

This 3D printed bicycle is highly customizable and can be easily disassembled and reorganized in a new way. It also weighs less than an average bike of its size.

SEE: These 3 industries are kickstarting the 3D printing revolution

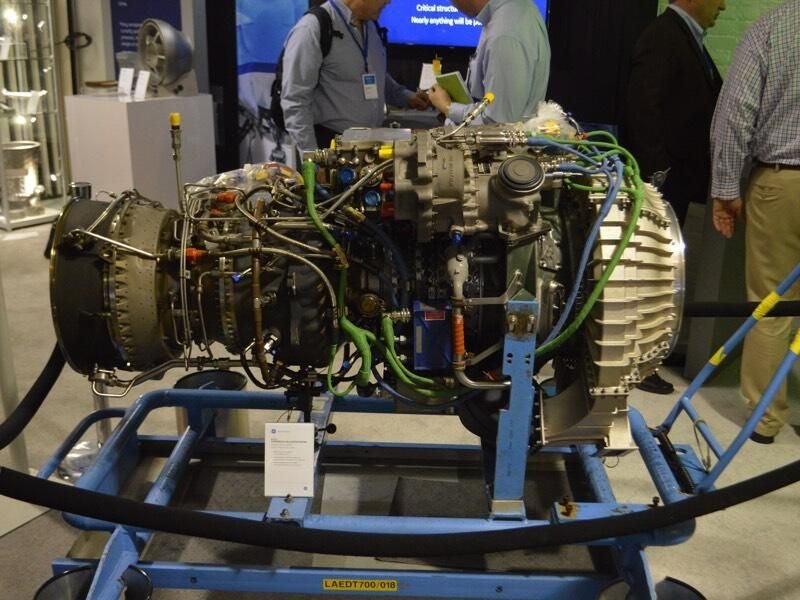

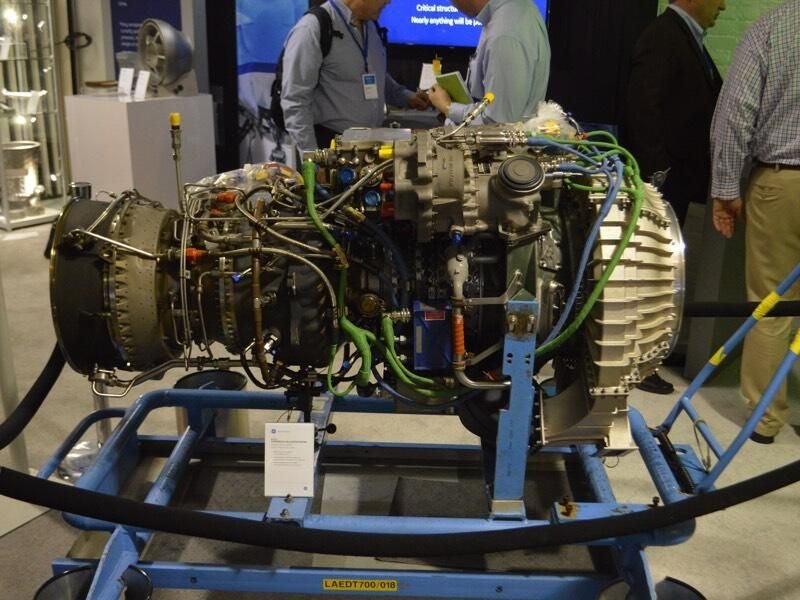

Helicopter engine

Helicopter engine

This helicopter engine is made of 40% 3D printed parts. Using additive technology, its creators were able to cut the weight down and increase the power of it. They also reduced the number of parts from 455 to 16.

SEE: These 3 industries are kickstarting the 3D printing revolution

3D printed drill bit

3D printed drill bit

This drill bit is more durable and reliable than its regularly-manufactured counterparts and is used for gas and oil exploration.

SEE: These 3 industries are kickstarting the 3D printing revolution

Skateboard

Skateboard

This lightweight skateboard was printed using 3D printing technology. It cut the cost of the skateboard by 25% and made it much lighter than others.

SEE: These 3 industries are kickstarting the 3D printing revolution

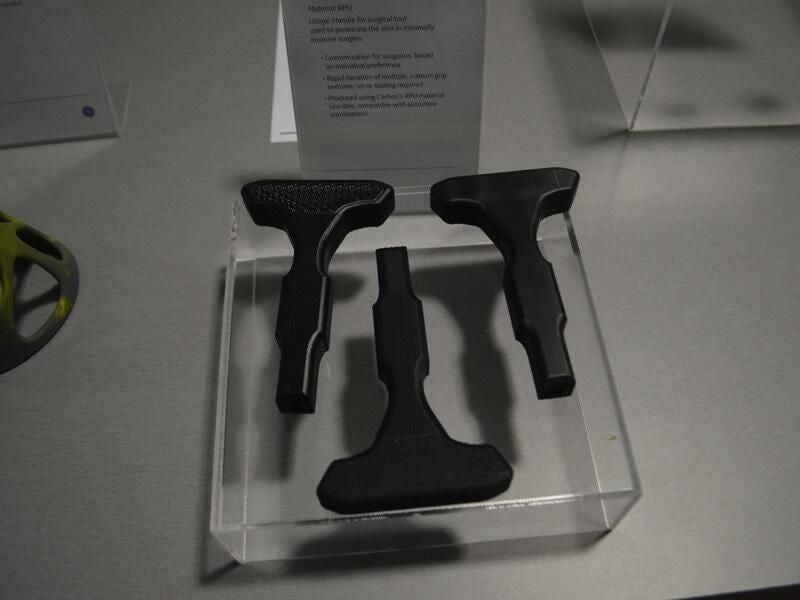

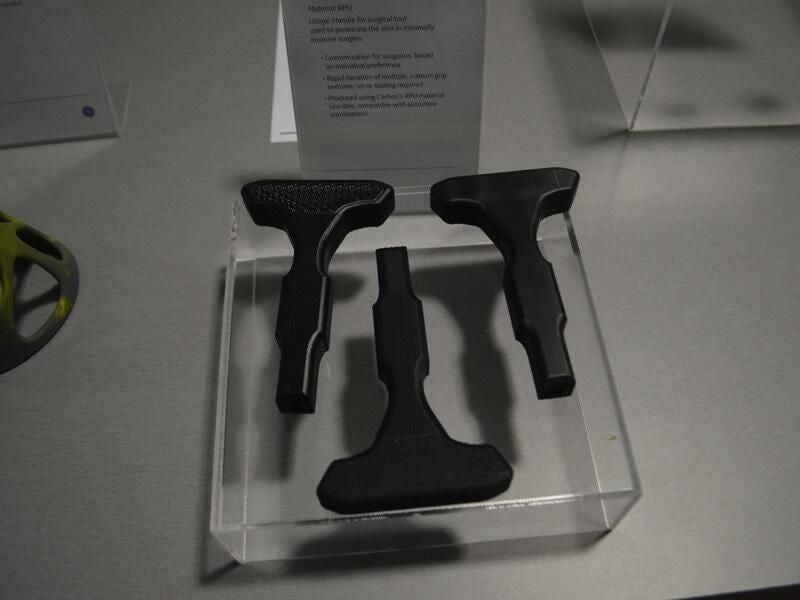

3D printed medical tool

3D printed medical tool

This tool is used by surgeons for procedures. The 3D printed device is designed for minimally-invasive surgeries and gives surgeons a durable product.

SEE: These 3 industries are kickstarting the 3D printing revolution

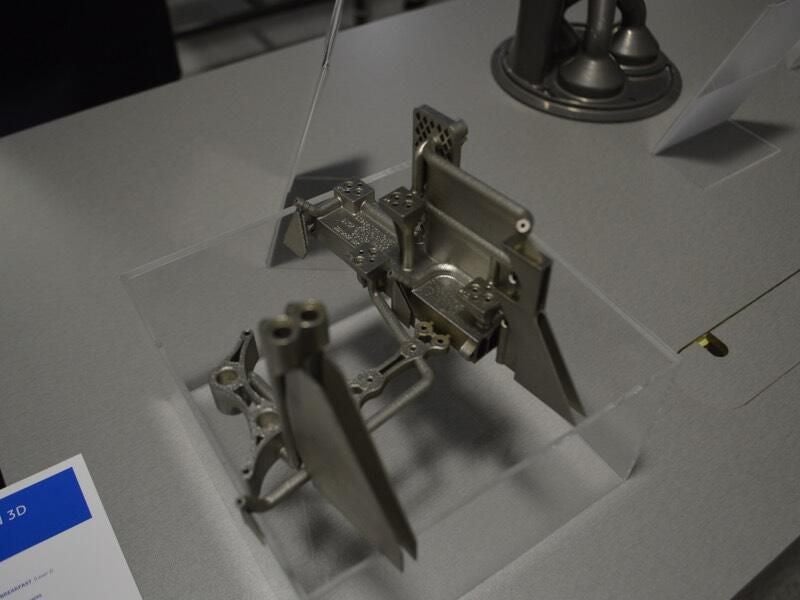

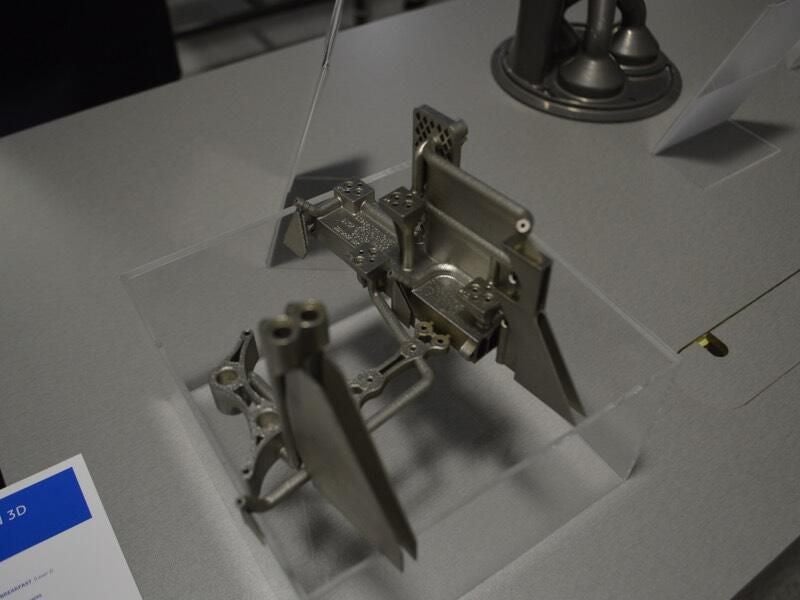

3D printed engine piece

3D printed engine piece

This tiny but important piece of metal is used inside engines and was very hard to customize. But with 3D printing, companies are able to create it quicker and make it more durable. They were also able to add minuscule design features that would not have been possible without 3D printing.

SEE: These 3 industries are kickstarting the 3D printing revolution

Heat exchanger

Heat exchanger

This copper heat exchanger for an engine was created using a 3D printer and was customized in a way that was difficult to make before 3D printing technology was available.

Also see

- 3D printing: A primer for business and technology professionals (Tech Pro Research)

- IT pro’s guide to 3D printing technologies (TechRepublic)

- 3D printing market hits $3.3B worldwide (ZDNet)

- 3D printing: A cheat sheet (TechRepublic)

- Photos: 10 major automakers using 3D printing today (TechRepublic)

- Semi-cyborg? 3D printer puts electronics directly on skin (CNET)

- 10 incredible prosthetics made with 3D printers (TechRepublic)

-

Account Information

Contact Jonathan Greig

- |

- See all of Jonathan's content